- What is room temperature bonding?

-

This is a type of bonding or joining. Its features are as follows:

- It does not use organic adhesives.

- It does not use energy from ultraviolet or laser emissions.

- The technology can join items merely by contact.

- What is interlayer room temperature bonding?

-

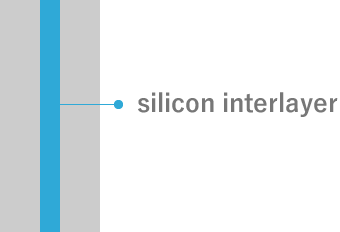

Hitherto, it has been possible to regularly join silicon wafers, etc., at room temperature, but it has not been possible to join ionic compounds (glass, etc.) and polymeric film, etc. What makes this possible is room temperature bonding via interlayer. One such typical product is silicon interlayer. Further, if using ion beam etching functions and scattering iron front and back of the silicon interlayer, the strength rises precipitously.

- What are the materials that can be joined together?

-

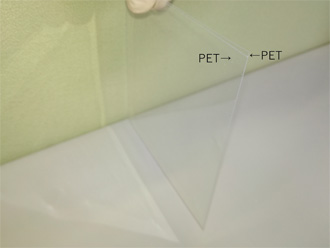

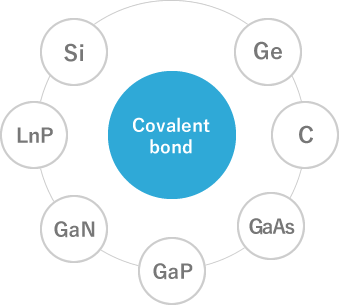

Basically, all materials can be joined. However, there are limits to the surface roughness of materials that can be joined. Basically, joining is possible if the surface roughness is approx. Ra 1nm Rmax 10nm. Materials that can achieve this actual surface roughness are silicon wafers for semiconductors, display glass, and sapphires, etc. Further, there are also joinable polymeric film products such as PET, PI, PC, and PEN, etc. Metals are comparatively difficult materials. Consult us regarding the individual materials.

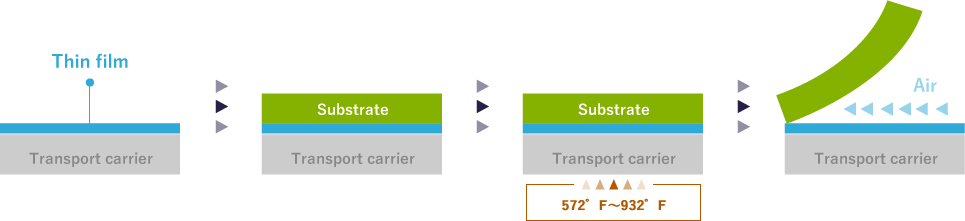

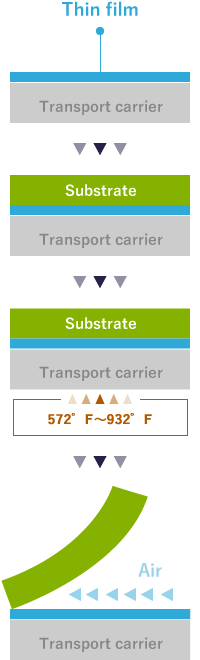

- Recently, there has been an increase in requests for all substrates to be thin. What is important at such times is the technology to join the thin substrate to a carrier with separation after processing has finished. Evidently, methods using adhesives are under examination, but it is said that the processes include a high-temperature heating process and so separation is a problem. Can room temperature bonding technology be using in these processes?

-

Room temperature bonding is a technology for which the strength can be adjusted according to the bonding. In recent years, there have been calls for a technology to join the thin substrate to a carrier substrate that can be separated after processing has finished. Room temperature bonding and separation technology is a technology that meets these demands.

Process

- If the flat and level condition of the substrate is poor, will room temperature bonding be impossible? Are there any bonding methods that can be used?

-

Bonding is possible if a flattening process such as CMP, etc., is used. Further, if a strong load such as roll-to-roll is applied, bonding is possible even if the flatness is rather poor.

CMP roll-to-roll

roll-to-roll

Latest results

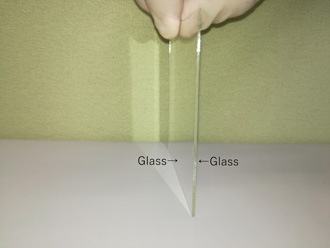

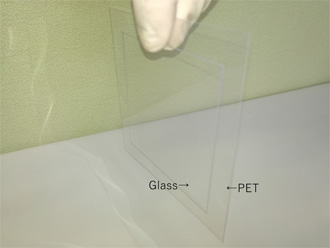

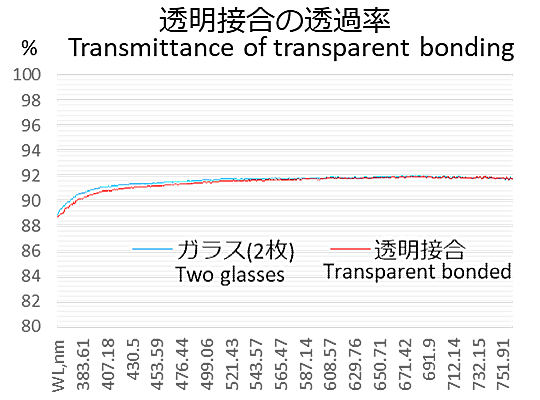

Transparent Room Temperature Bonding

Conventional Si interlayer bonding is colored brown. Transparent room temperature bonding of new technology does not have coloring. We are looking for applications that need this technology.

Room temperature bonding which maintained transparency (99% or more) with our new transparent interlayer became possible.

Application field of transparent room temperature bonding

- Optical element MEMS

- Display

- Optical element of laser

More than 99% permeability

We are exhibiting samples of transparent room temperature bonding.

We are researching various bonding methods and surface processes in addition to room temperature bonding to be able to contribute to all kinds of bonding methods.

Feel free to consult us